At the beginning of the Pandemic, I did a blog about making mayonnaise. At that point I was simply just excited to be able to make it and to be able to do so fairly consistently. However recently had a couple of occasions where the mayo failed. This will ultimately happen if there’s too much oil per egg protein. I’d also observed that I never quite used that whole cup of oil per egg yolk. So I’ve been determined to figure it out so that my efforts can be 100% consistently successful. That’s what this blog is about.

Essentially I’ve come to understand that one needs to multiply the weight of the egg yolk by 7.66. More than that, and it will fail. Less is OK. The less oil, the thicker the mayo.

Here is the text version of the basic 2 yolk mayo. Even if you never open up my little ap with the formulas all built in, the following proportions should give you a decent and dependable mayo:

(Originally from Michael Ruhlman’s Ratio)

Generally, one egg will yield a cup of mayonaise.

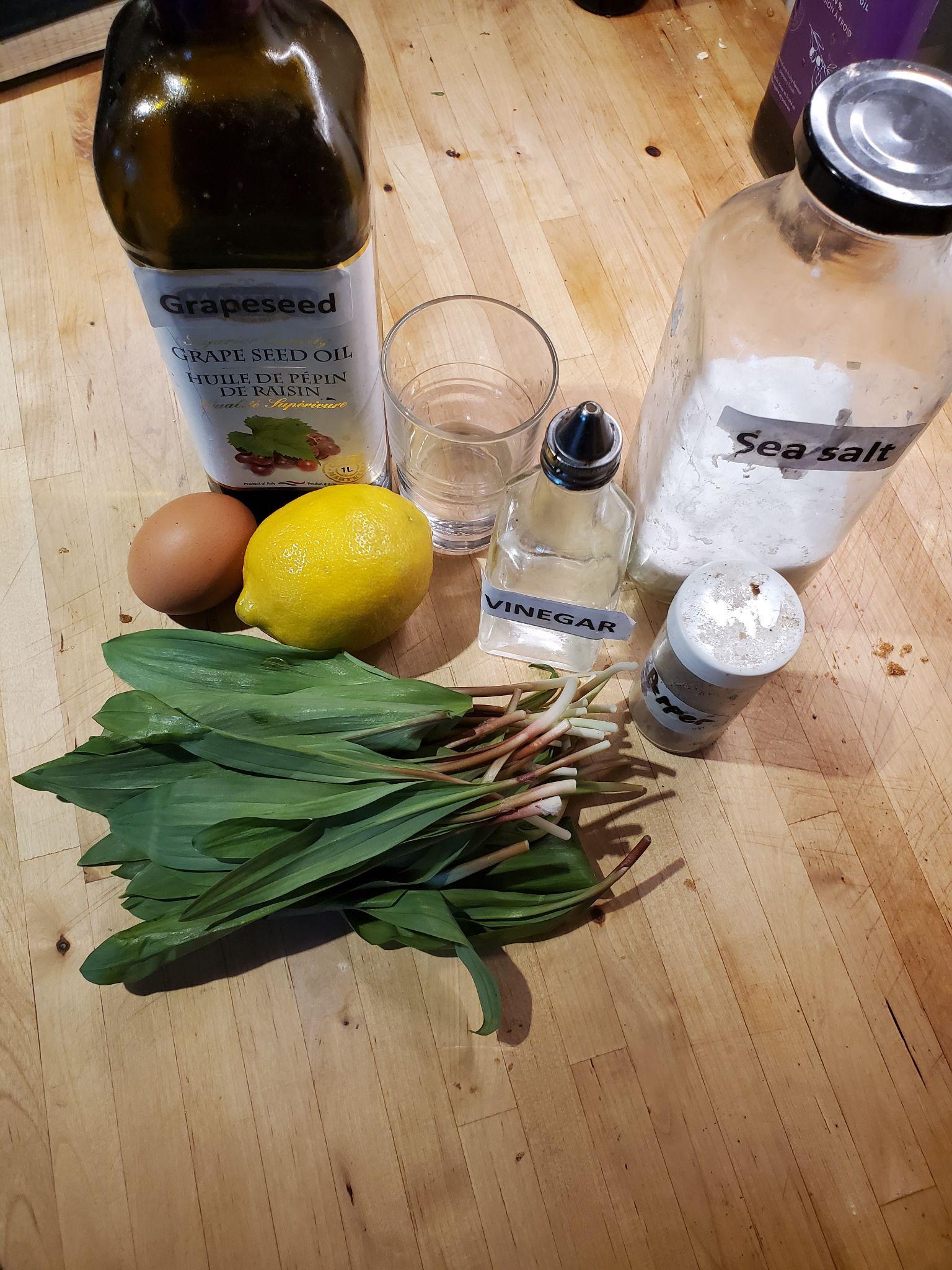

Ingredients

This will make 500ml mayonnaise.

2 egg yolks

330 g grapeseed oil

1 tsp salt

2 tsp water

2 tsp lemon juice

2 tsp vinegar

Method:

This recipe assumes you are using my little mayo ap.

- Use an immersion blender and the mixing jug that came with it, or alternately a wide mouth 1 L mason or salsa jar.

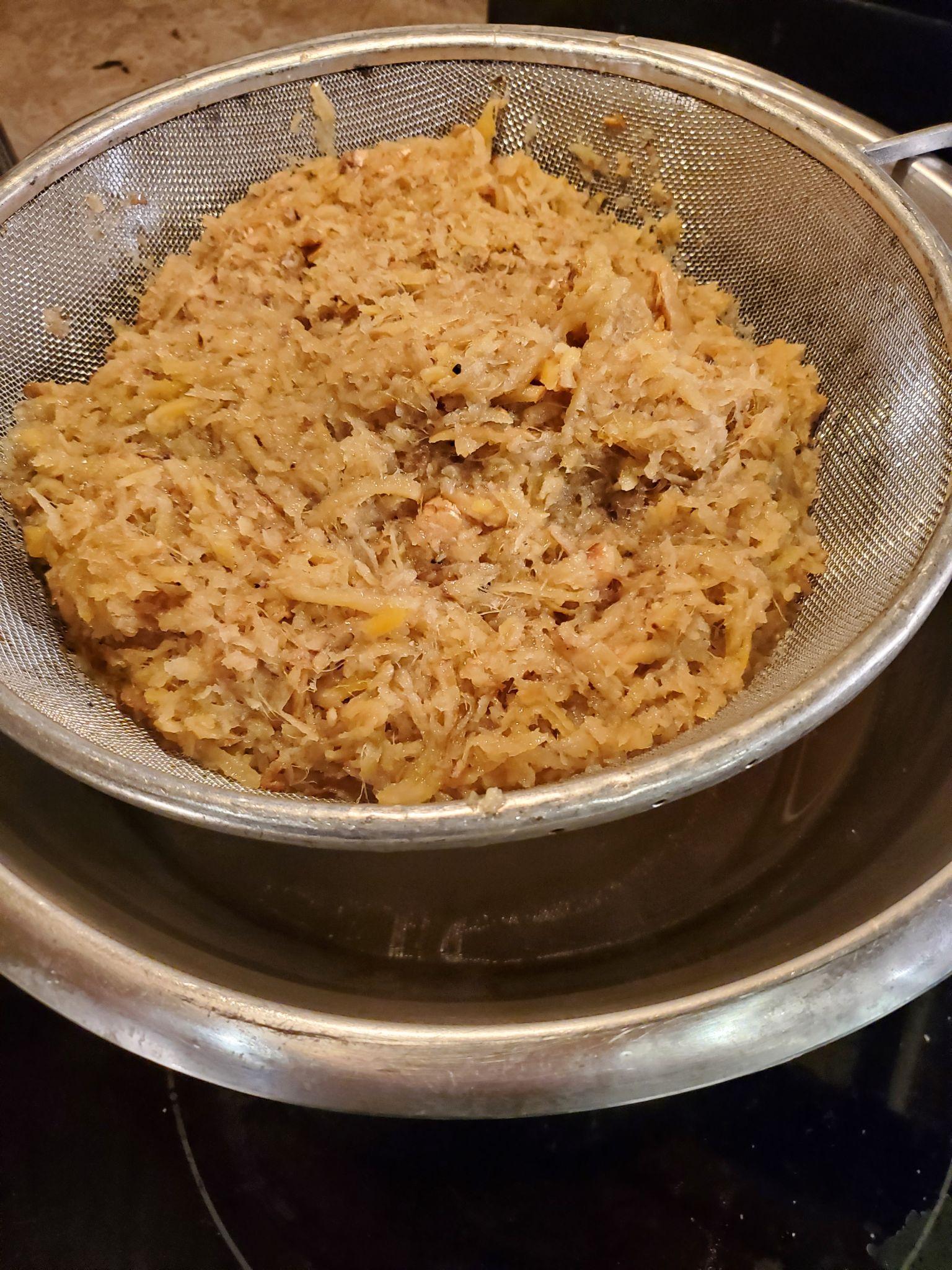

- Place the immersion blender container/jar on a weigh scale and tare to 0. Separate the eggs, putting the yolk in the immersion blender mixing jug. Input the yolk weight in the ap, then weigh/measure the oil, vinegar,lemon juice, water and salt.

- Add the vinegar,lemon juice, water and salt to the egg yolks and whirr around with the immersion blender until well mixed.

- Slowly add the oil a little at a time to gain emulsion. Continue until all the oil is used.

- Taste for lemon and salt at the end.

- Refrigerate.

Other considerations and notes

- Ensure your lemon is fresh. A ‘getting slightly bitter’ lemon can be disguised in other dishes but not this.

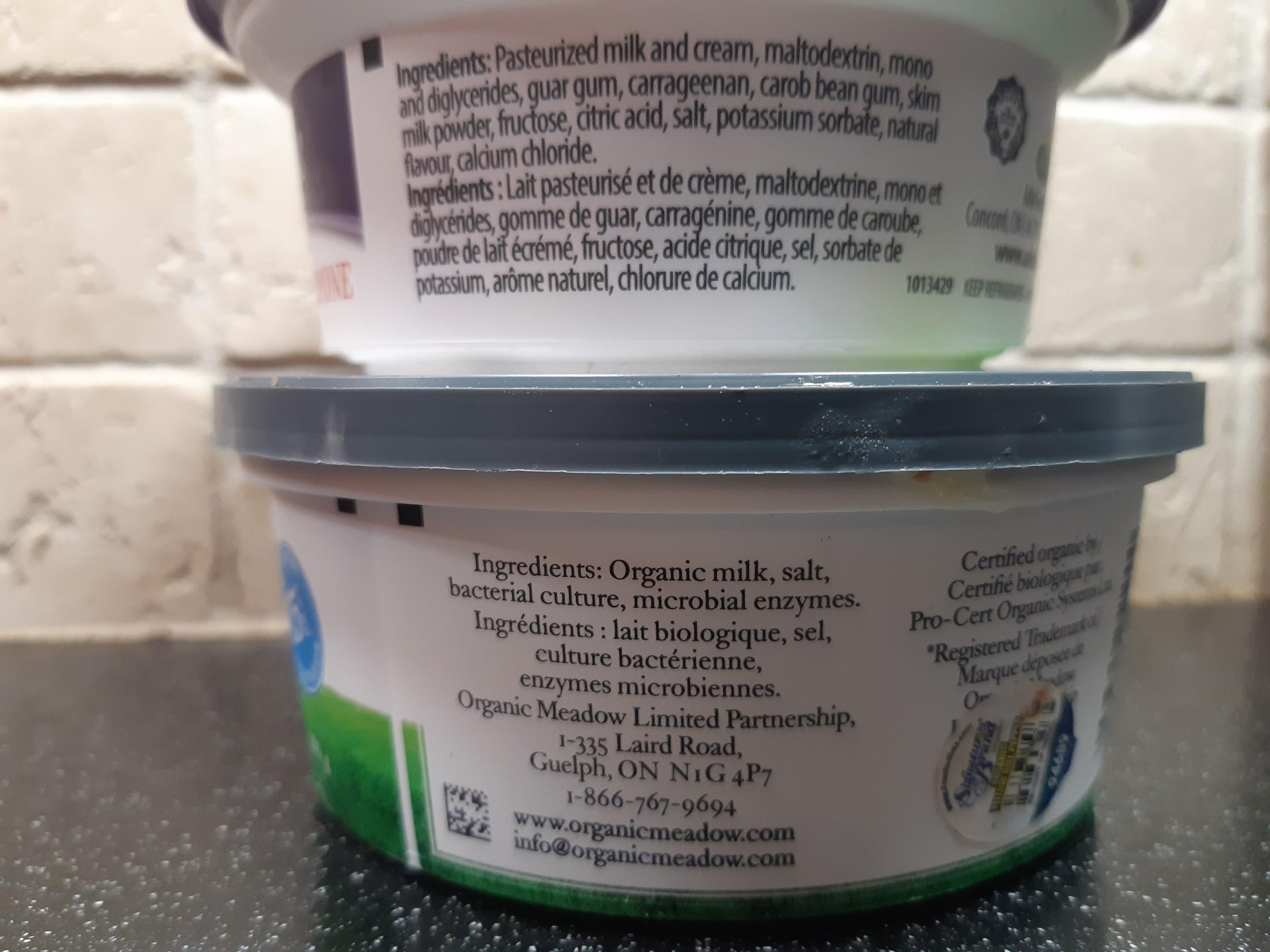

- Ensure your oil is fresh and as tasteless as possible. Grapeseed oil is the best for this, but do taste before using. If there is any harshness or even a hint of rancidity, it will shine through in the mayo, and not in a good way.

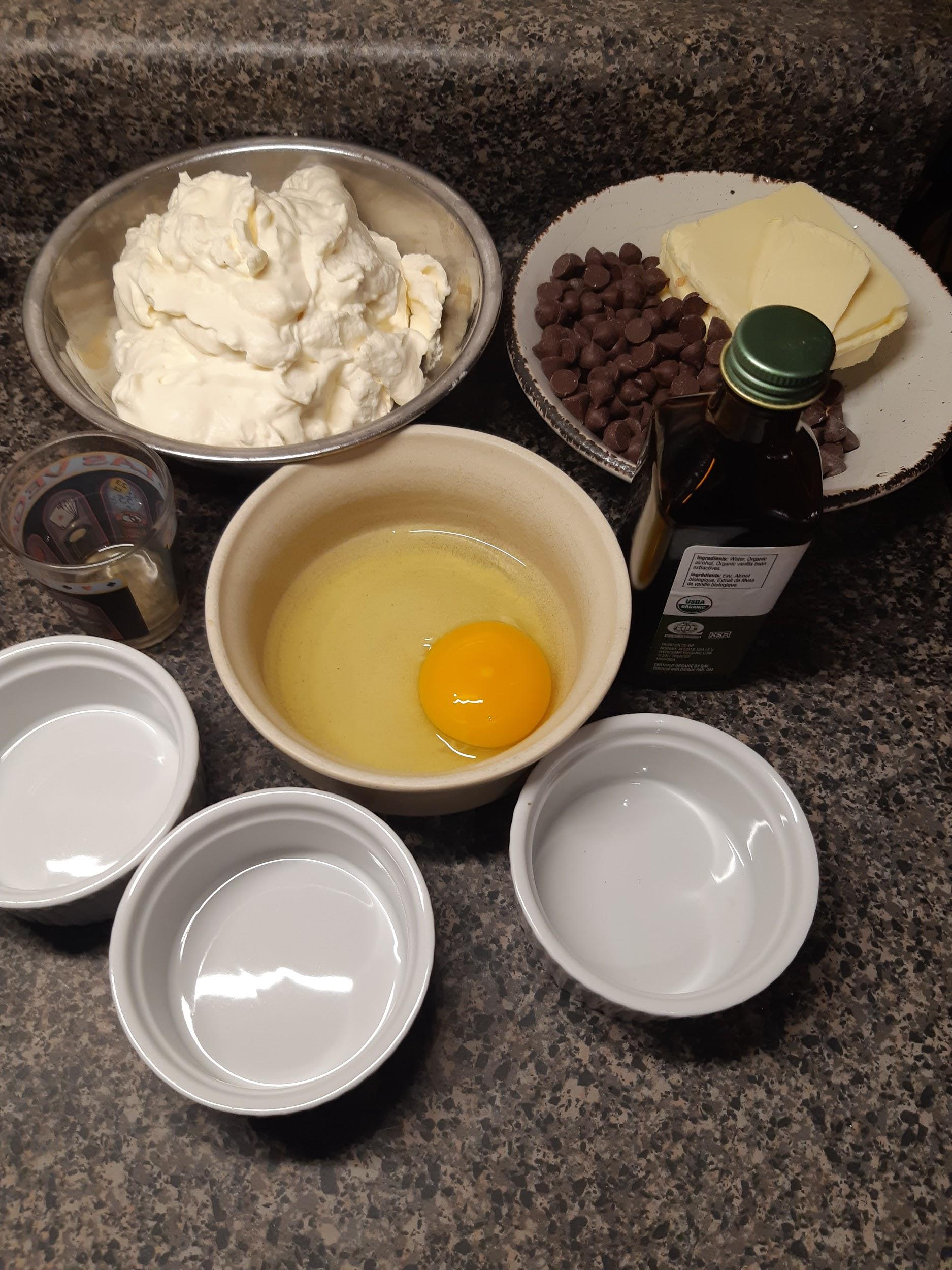

- I like to make this simple 2 cup base. If I want to make variants such as dijon mayo, or hot mayo, I’ll scoop some in a 125ml ramekin or jar and go from there. There are so many variations! Dijon mayo (add a tsp of dijon to the ramekin size), or hot versions with cayenne, hot sauce, Harissa immediately come to mind. Adding ketchup leads you down the road to a Thousand Islands dressing.

- Mayo and Cesar dressing are definitely culinary siblings. Both involve egg, oil and lemon juice. Both are emulsified. Cesar merely adds garlic, herbs, pepper, hot sauce and parmesan.

- If you do mess it up, and the mayo breaks, pour the failed mayo into a measuring cup. Add a teaspoon of water and another yolk in the mixing jar. Slowly add in the broken mayo. Or you could use it as it is either a vinaigrette base, a dressing for coleslaw or potato salad, or as noted above, make into a Cesar dressing.

- If you do need large quantities of mayo for that big summer BBQ coleslaw, you can do a quickie version that may not give you the full emulsification of that nice jar in the fridge, but will go a lot faster. Use the ap file to scale up the quantity you want, use whole eggs instead of only the yolk, and work with a food processor. It will also be a lot cheaper than buying all that mayo.